Led Par 64 Lights Factory – 200W COB LED waterproof IP65 par light – Beyond

Led Par 64 Lights Factory – 200W COB LED waterproof IP65 par light – Beyond Detail:

200W COB LED waterproof IP65 par light

- Light source:200W cob led+12x10w RGBW led

- New type high brightness and light output lens

- Use 180°reversed big vision colorful LCD display

- High powrful and good colors

- IP powercon in/out socket

- Dimension: 29*28*21.5cm

- NW:6.5 kgs

- Good to use on stage or architectural lighting

- Cental COB led can do white or RGBW

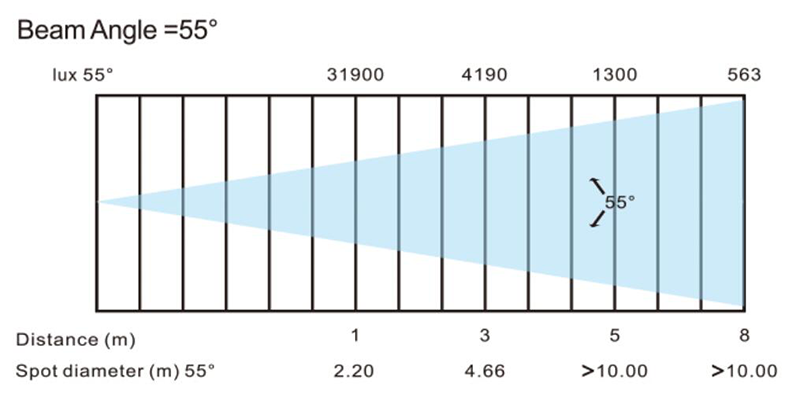

- Beam angle: 55 degree

Technical Parameters

| Optics | Construction | ||

| Led source | 1pcs 200W white & 4-in-1 rgbw COB led + 12pcs 10W RGBW led | Display | Touch Display |

| Beam angle | COB led 55 degree; RGBW led 25 degree | Data In/Out socket | waterproof DMX in/out socket |

| Power Consumption | 350W | Power Socket | Waterproof Powercon in/out |

| Control | Protection Rating | IP65 | |

| Control Modes | DMX512/Auto Run | Specification | |

| DMX mode | COB White+RGBW :12/8 Channels | Dimension | 282*213*290mm; |

| COB RGBW+RGBW:10/14 Channels | NW | 6.5 kgs | |

| Features | Standard package:carton;Flight case in optional | ||

| Dimmer:0~100% smooth dimming ;two dimmer model in optional( delay or without delay) | Certification:CE,ROHS | ||

LUX Date

Product Effect

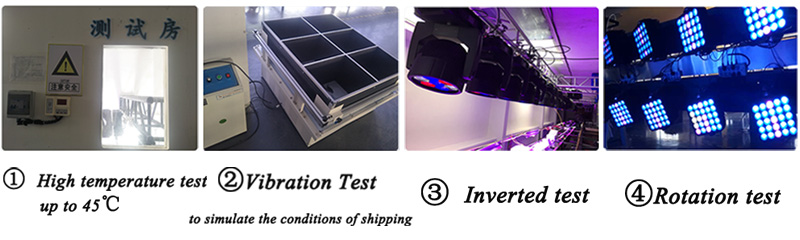

Product Test Process

| There are 6 normal steps for QC control process: | |||

| Step 1: all materials passed 100% IQC inspect | |||

| Before send materials to workshop and start to produce, our IQC technicians will inspect them. | |||

| And only the materials are approved to send to workshop if they are qualified. | |||

| All units lights will | |||

| Step 2: at least 48 hours aging test before packing | |||

| All unit lights will be 100% QC inspect and takes around 48- 72 hours aging test | |||

| Step 3: hang testing | |||

| Each batch production we will select certain percent to do hang or rotating test | |||

| Step 4 : Environment high temperature testing | |||

| we did two parts test for high temperature testing : | |||

| A: testing during the product still in R & D | |||

| B: testing for each batch production | |||

| Usually we test the temperature reach to around 45℃ | |||

| Step 5 : vibration test–simulating transit environment | |||

| each batch production we will select certain percent to test to make sure the goods is safe in transport | |||

| Step 6: waterproof testing (only for IP65 lights) | |||

| all waterproof lights we will do waterproof test to see can it be work fine under rain |

Goods Shipping

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for Led Par 64 Lights Factory – 200W COB LED waterproof IP65 par light – Beyond , The product will supply to all over the world, such as: Honduras, Bulgaria, Danish, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.